وُضعت جميع المواصفات الفنية وخطط التكوين وتوصيات التطبيق بالتعاون بين قسمي البحث والتطوير والمشاريع في بوكسين، ووُضعت اللمسات الأخيرة عليها تحت إشراف مديرنا الفني، ]السيد ليو[.

|

|

|

|

لماذا إعادة تدوير الأفلام البلاستيكية؟

تستخدم الأغشية البلاستيكية والأكياس المنسوجة PP (البولي بروبيلين) و PE (البولي إيثيلين) على نطاق واسع من المواد البلاستيكية المرنة ، والتي توجد عادة في الحياة اليومية والتطبيقات الصناعية. تشمل أفلام PE أفلام المهاد الزراعية ، وأفلام الدفيئة ، والأغلفة اللاصقة ، وأكياس التسوق ، وأكياس القمامة المصنوعة من البولي إيثيلين منخفض الكثافة (LDPE) والبولي إيثيلين الخطي منخفض الكثافة (LLDPE). من ناحية أخرى ، كثيرا ما تستخدم أفلام PP في مواد التعبئة والتغليف مثل أغشية BOPP وطبقات التغليف المرنة المركبة.

تستخدم الأكياس البلاستيكية المنسوجة ، المصنوعة بشكل أساسي من خيوط PP المنسوجة ، على نطاق واسع لتعبئة البضائع السائبة مثل الحبوب والأعلاف الحيوانية والأسمدة والأسمنت. وهذا يشمل الأكياس المنسوجة القياسية وكذلك الأكياس الجامبو أو الأكياس السائبة (أكياس FIBC). نظرا لاستخدامها العالي ودورة حياتها القصيرة ومصادرها المتنوعة - من الحقول الزراعية (نفايات أغشية المهاد) ، والقطاعات الصناعية واللوجستية (أفلام التعبئة والتغليف والأكياس المنسوجة) ، إلى استخدام المستهلك (أكياس التسوق وأكياس البريد السريع) - تصبح هذه المواد نفايات واسعة الانتشار. نظرا لصعوبة تحللها بشكل طبيعي ، فإن هذه المواد البلاستيكية اللينة المهملة تستمر في البيئة ، مما يتسبب في "تلوث أبيض" كبير وإهدار الموارد إذا لم يتم إعادة تدويرها بشكل صحيح.

مع التقدم السريع في تقنيات إعادة التدوير, تتيح آلات إعادة تدوير الأفلام البلاستيكية الاحترافية الآن المعالجة الفعالة وتحويل هذه المواد الصعبة سابقا إلى كريات معاد تدويرها عالية الجودة. يمكن إعادة إدخال هذه الكريات المعاد تدويرها في إنتاج منتجات بلاستيكية جديدة. تقلل هذه العملية بشكل فعال من الاعتماد على البلاستيك البكر ، وتعزز الاستخدام الدائري للموارد البلاستيكية ، وتساهم بشكل كبير في الاستدامة البيئية.

ما الذي يمكن إعادة تدويره؟

توفر خطوط إعادة تدوير الأفلام البلاستيكية الخاصة بنا حلول فرز وغسيل فعالة وموثوقة لمختلف المواد البلاستيكية اللينة ، بما في ذلك LDPE و HDPE و PP و PE والمزيد. نحن نقدم عمليات إعادة تدوير مرنة وقابلة للتخصيص مصممة خصيصا لقدرات الإنتاج المختلفة وأنواع المواد الخام (مثل الأكياس البلاستيكية والأفلام) ، مما يلبي تماما احتياجات كل من العمليات الصغيرة والمتوسطة ومصانع إعادة التدوير الصناعية واسعة النطاق.

تشمل المواد النموذجية القابلة لإعادة التدوير ما يلي:

|

الأفلام الزراعية |

الأفلام المصنفة من النفايات الصلبة البلدية (MSW) |

أفلام السوق |

أكياس منسوجة |

أكياس جامبو (أكياس سائبة / FIBC) |

كيف تعمل آلة إعادة تدوير الأغشية البلاستيكية؟

اعتمادا على نظافة المواد الخام ، تتبع عمليات إعادة تدوير الأغشية البلاستيكية عموما مسارين متميزين:

|

1. عملية المواد الملوثة بشدة(على سبيل المثال ، الأفلام الزراعية التي تحتوي على ما يصل إلى 80٪ من الرمال) يتطلب ذلك عملية كاملة "تمزيق → الغسيل → إزالة الملوثات → التجفيف": |

|

2. عملية المواد النظيفة المباشرة(على سبيل المثال ، القطع الصناعية أو أفلام التغليف النظيفة) يمكن للمواد الأنظف تجاوز الغسيل والانتقال مباشرة إلى أنظمة التكوير: |

عملية إعادة التدوير: فيلم المنسوجة حقيبة غسل خط Pelleitizing

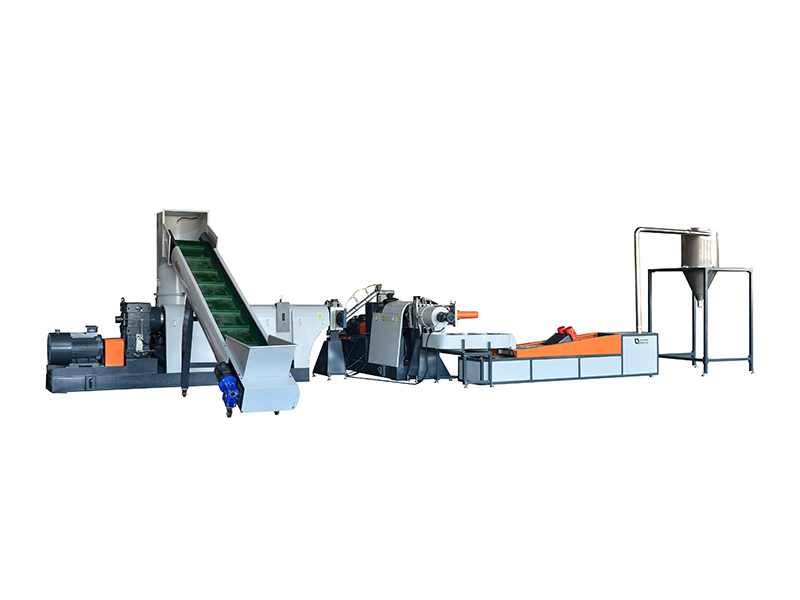

يشمل خط إعادة تدوير الأكياس المنسوجة وأغشية PP / PE بشكل عام المعالجة المسبقة ، والتقطيع ، والغسيل ، والتجفيف ، والذوبان ، والتكوير. يتضمن المبدأ الأساسي إزالة الشوائب من نفايات البلاستيك ميكانيكيا وبمساعدة الماء, متبوعا بالتجفيف والبثق من خلال آلة تكوير لإنتاج كريات بلاستيكية معاد تدويرها عالية الجودة مناسبة للتطبيقات النهائية.

عملية إعادة التدوير النموذجية:

1. جمع المواد والمعالجة المسبقة:

اجمع أغشية النفايات المتناثرة والأكياس المنسوجة ، ثم قم بإزالة الملوثات غير البلاستيكية (الملصقات والمعادن) إما يدويا أو ميكانيكيا. افصل المواد غير المتوافقة (مثل PVC) ، وقم بتنظيف الشوائب الكبيرة بشكل مبدئي مثل الرمل والتربة.

2. التقطيع (الخشنة والناعمة):

يتم تمزيق الأغشية البلاستيكية الكبيرة والأكياس المنسوجة إلى قطع أصغر باستخدام آلات تمزيق أو كسارات (مفردة / مزدوجة الرمح). تقوم الآلات المتخصصة (على سبيل المثال ، كسارات Boxin Machinery برذاذ الماء) بسحق المواد وغسلها مسبقا في وقت واحد ، مما يقلل من الغبار ويزيل بعض الرمل والشوائب.

3. الغسيل:

يتم تنظيف البلاستيك المبشور جيدا باستخدام مراحل غسيل متعددة. أولا ، تستخدم غسالات الاحتكاك شفرات دوارة عالية السرعة لإزالة الأوساخ العنيدة. بعد ذلك ، تفصل خزانات الحوض العائم بين الملوثات الثقيلة (الرمل) والبلاستيك الأخف وزنا. يمكن لعمليات الغسيل الساخن (باستخدام الماء الساخن والمنظفات) إزالة الحبر والمواد اللاصقة والزيوت ، مما يعزز نقاء وقيمة المعاد تدويرها.

4. الجفاف والتجفيف:

بعد الغسيل ، تحتوي الأجزاء البلاستيكية على رطوبة كبيرة ويتم تجفيفها باستخدام مجففات الطرد المركزي (الرأسية أو الأفقية). يتم تقليل الرطوبة المتبقية بواسطة مجففات الهواء الساخن إلى أقل من 5٪. قد تستخدم العمليات المتقدمة مجففات الضغط ، والتي تزيل الرطوبة ميكانيكيا وتذوب البلاستيك جزئيا لتحسين كفاءة التكوير اللاحقة.

5 . بثق الذوبان:

تدخل الرقائق البلاستيكية النظيفة والمجففة إلى آلات بثق التكوير ، حيث يتم تسخينها وصهرها. تعمل آلات البثق أحادية المرحلة أو مزدوجة المرحلة المجهزة بالتحكم التلقائي في درجة الحرارة وأنظمة التفريغ الفراغي على إذابة الرقائق بشكل موحد وإزالة الرطوبة المتبقية والمواد المتطايرة. تضمن المرشحات الذائبة النقاء قبل البثق.

6. التبريد والتكوير:

يتم تبريد البلاستيك المذاب وتقطيعه إلى كريات باستخدام إما أجهزة تكوير الحلقة المائية (قطع الوجه الساخن) أو أجهزة تكوير الخيوط (قطع الخيوط). أجهزة تكوير الحلقة المائية ، المفضلة ل PE / PP ، تبرد الكريات بسرعة بعد القطع. تقوم حبيبات حبلا بثق الخيوط البلاستيكية وتبريدها ، ثم تقطيعها إلى كريات أسطوانية موحدة. تخضع الكريات النهائية ، عادة 2-5 مم ، لفحص الاهتزاز أو فرز الهواء لإزالة الغرامات ثم يتم تخزينها في صوامع لاستخدامها في المصب.

طوال عملية إعادة التدوير ، تعد إعادة تدوير المياه ومعالجة مياه الصرف الصحي أمرا بالغ الأهمية. ينتج عن الغسيل مياه عادمة كبيرة تحتوي على منظفات ومواد صلبة ، والتي يجب إعادة تدويرها عبر أنظمة الترسيب والترشيح لتقليل التأثير البيئي. تدمج خطوط إعادة التدوير الحديثة أدوات التحكم الآلي للتشغيل المستمر ، مما يعزز الإنتاجية ويقلل من كثافة اليد العاملة.

وحدات المعدات والتكنولوجيا الأساسية

يتضمن خط إعادة تدوير البلاستيك اللين الكامل العديد من الوحدات الأساسية التي تعمل معا لضمان إعادة التدوير الفعالة:

|

الناقلون:تنقل الناقلات الأفقية والمائلة المواد بين المراحل ، مما يقلل من المناولة اليدوية ويعزز استمرارية سير العمل. |

|

آلات التقطيع / الكسارات:تتعامل آلات التقطيع المصممة خصيصا مع المواد البلاستيكية الناعمة ، وتقسيم الحزم الكبيرة إلى أحجام يمكن التحكم فيها مناسبة للغسيل والتكوير. |

|

غسالات الاحتكاك:تقوم الشفرات الدوارة عالية السرعة بفرك الملوثات وفصلها ميكانيكيا عن البلاستيك ، مما يعزز النظافة بشكل كبير. |

|

خزانات الحوض العائم (خزانات الغسيل):افصل البلاستيك عن الشوائب باستخدام اختلافات الكثافة ، وإزالة الملوثات الثقيلة بشكل فعال. |

|

مجففات الطرد المركزي:قم بإزالة الماء بسرعة من الشظايا البلاستيكية ، مما يقلل من محتوى الرطوبة لتسهيل التكوير الفعال. |

|

مجففات الهواء الساخن:مزيد من البلاستيك المغسول الجاف إلى مستويات الرطوبة المثلى (<5٪) ، مما يمنع العيوب أثناء البثق. |

|

الطارد (الملدنات):قم بإذابة الرقائق النظيفة وتجانسها ، مما يؤدي إلى تحضير البلاستيك بشكل حاسم للتكوير المستقر. |

|

أنظمة التكوير:تحويل البلاستيك المصهور إلى كريات موحدة عبر تقنيات تكوير الحلقة المائية أو حبلا. |

|

معدات التبريد والنقل:ضمان التبريد السريع ونقل الكريات إلى مرافق التخزين, الحفاظ على سلامة الحبيبات وجودتها. |

أدت التحسينات المستمرة في هذه المكونات الأساسية ، مثل الشفرات المحسنة المقاومة للاهتراء ، وتدفقات المياه المحسنة ، وتقنيات الترشيح الذائب المتقدمة ، إلى زيادة الإنتاجية وكفاءة الطاقة والاستقرار التشغيلي بشكل كبير.

التطبيقات والاستخدامات النهائية

تحتوي كريات PP / PE المعاد تدويرها على تطبيقات نهائية متنوعة, تتأثر قابليتها للاستخدام بمصادر المواد الخام وتقنيات المعالجة. تشمل التطبيقات النموذجية ما يلي:

-

منتجات الفيلم: أكياس القمامة وأكياس التسوق وأفلام المهاد الزراعية. قد تختلف الجودة. غالبا ما تنتج الأفلام الزراعية المعاد تدويرها أغشية نشارة سوداء أو عبوات منخفضة الجودة.

-

المنتجات المصبوبة بالحقن: الأدوات المنزلية ، وصناديق التخزين ، والدلاء ، والمنصات ، وقطع غيار الأجهزة ، والألعاب ، ومكونات السيارات ، إلخ. تقلل الكريات المعاد تدويرها بشكل كبير من تكاليف الإنتاج.

-

الألياف والمنتجات المنسوجة: كريات PP المعاد تدويرها للأكياس المنسوجة, الحبال, والتكسية الأرضية. يمكن أيضا غزل كريات البولي إيثيلين إلى ألياف قصيرة للمواد غير المنسوجة.

-

الأنابيب والملامح: يشيع استخدام HDPE المعاد تدويره لأنابيب الري الزراعية وأنابيب القنوات وأنابيب الصرف والملامح للتزيين المركب والأسوار وإطارات النوافذ.

-

المواد المعدلة والمخلوطة: تنتج الكريات الممزوجة باللدائن أو المواد المضافة مواد متخصصة مثل نعال الأحذية, البلاستيك المثبط للهب, وإضافات بناء الطرق, توسيع تطبيقات البلاستيك المعاد تدويره.

تؤثر نقاء وجودة الكريات المعاد تدويرها بشكل مباشر على تطبيقاتها النهائية. يمكن أن تدخل الكريات عالية الجودة إلى الأسواق الأكثر تطلبا, بما في ذلك تغليف المواد الغذائية والأجهزة غير المباشرة. عادة ما تخدم الكريات متوسطة الجودة السلع الاستهلاكية المعمرة أو مواد البناء أو التعبئة والتغليف. الكريات منخفضة الجودة مناسبة للمركبات الخشبية والبلاستيكية أو المنتجات غير المطلوبة, أو تتم معالجتها بشكل أكبر في زيوت الوقود من خلال الانحلال الحراري الكيميائي.

بشكل عام, تغطي كريات PP / PE المعاد تدويرها نسبة كبيرة من إنتاج البلاستيك, تستخدم على نطاق واسع في نفخ الأغشية, قولبة الحقن, البثق, وعمليات التصنيع الأخرى. تشمل المنتجات اليومية المصنوعة من البلاستيك المعاد تدويره الأكياس والحاويات والأثاث والعديد من المكونات الصناعية. من خلال التعديل والمزج المناسبين ، يمكن للبلاستيك المعاد تدويره أن يدخل الصناعات الراقية مثل المنسوجات والسيارات والإلكترونيات ، مما يحل محل البلاستيك البكر بشكل فعال ، ويقلل من تكاليف الإنتاج ، ويساهم بشكل كبير في الاستدامة البيئية.

SA

SA

English

English 简体中文

简体中文 Русский

Русский España

España عرب .

عرب .